GSP Coatings can provide high quality finishes that meet the stringent demands required by the manufacturing industry on a wide spectrum of part geometries and sizes. Our state of the art processes along with ISO 9001:2015, and AS9100:2016 certified Quality System allows us to provide close tolerance finishes for your parts.

Utilizing a variety of poly tapes, grounding dots, and UV curing polymers, our skilled masking team can provide solutions for complex masking requirements. Custom dye cuts are available by request and most of the popular sizes of tapered and pull through plugs are in house.

Our large inventory of racks allows us to accommodate most any part geometry. When standard racks can’t get the job done, our experienced team can also provide bespoke racking solutions.

RoHS/REACH statements can be provided upon request at time of order.

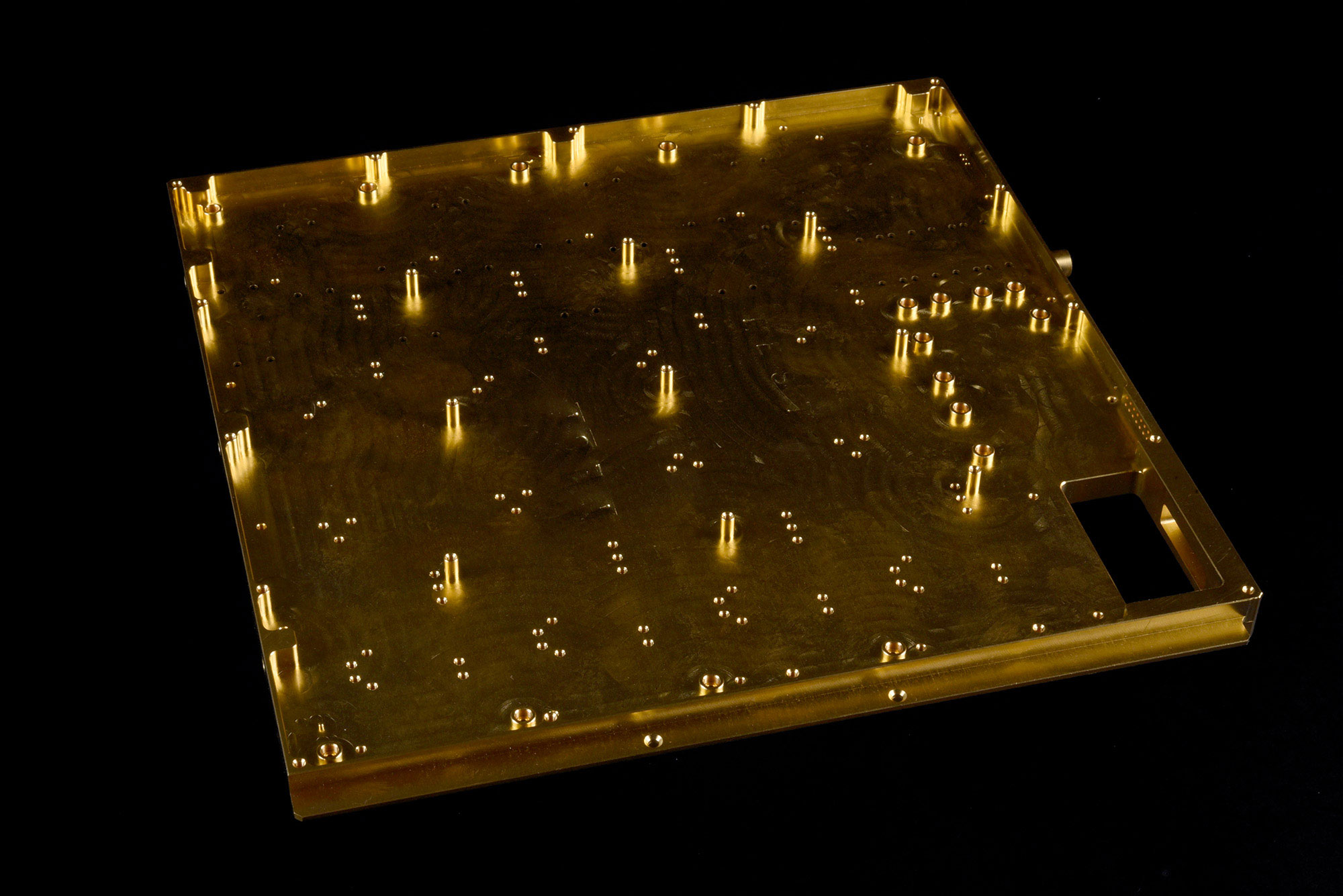

anodize

We offer clear or colored anodize and can provide both satin and standard finishes. Our anodic coatings meet the requirements of an assortment of industry specification such as MIL-A-8625 Type II, AMS-2471/AMS-2472, ASTM B580 Type B thru F, and more. Certifications of conformance can be provided with your order. From large workpieces up to 6.5 feet long, to small pieces the size of a grain of rice, we’ve got you covered.